| April

14/15th - Head Gasket and Pedal Spring Replacement For

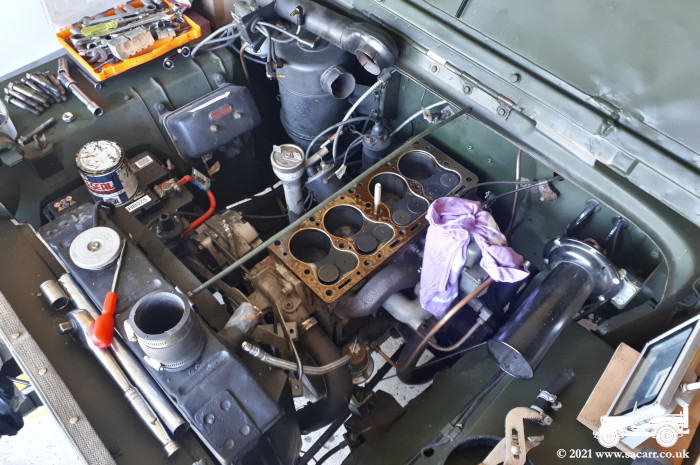

a while, I've suspected a head gasket leak on the GPW. Coolant level was

dropping, the radiator overflow was blowing coolant and the engine

sounded lumpy at start up. When I changed the oil, just before moving

house, there was a little water in the sump. The first thing I did was

drain the oil and coolant. With the radiator empty, I fitted a new drain

cock as the wings on the old one were damaged. Next job was to remove

the oil filter and the radiator hose, then I could unbolt the cylinder

head. |

|

|

|

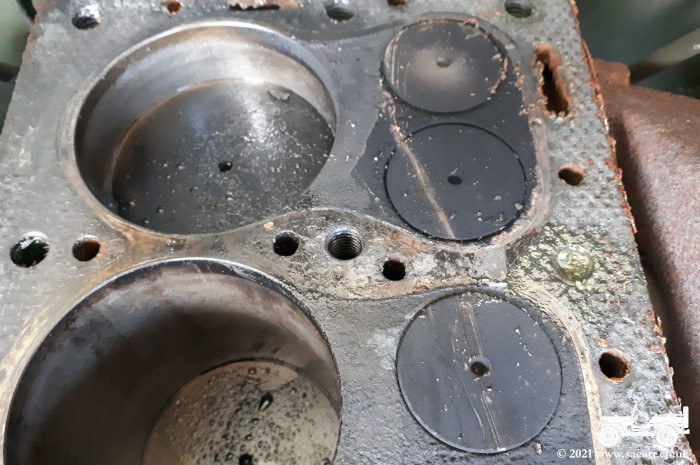

| I found my cylinder head leak between cylinders 3 and 4. I ordered a new gasket and set about to change it on April 14th. That's when it got frustrating. When the engine was rebuilt, I knew that bolt number 1 was stripped in the block. I understood from the engine rebuilder that he tapped a new larger thread in the block and put a bigger bolt in. However, once the head was off, it was clear he didn't bother. What he did do was to tap the cylinder head and put a bolt in, giving the impression it was tightening up on the block when all it was actually doing was filling the hole in the head. |

|

|

|

| The engine is old, pre-war in fact and isn't the greatest. I didn't fancy trying to cut an even bigger thread in the block, which would also require the head being drilled out. Equally, I didn't want to put a helicoil in, since the already oversized hole was so close to the water passage. My solution was to drop a large nut and washed down the cooling passage, attached to cotton. A threaded rod was coated in epoxy and passed through its hole before being screwed into the washer and nut. Effectively the block now has a permanent stud. Another nut was fastened on overnight to hold it vertical while the epoxy cured. |

|

|

|

| On the 15th, the gasket was fitted and head bolts torqued up, nipping up the nut on the new stud at the same time. Once back together, I gave it a run, but got some weeping passed the threads in the new stud as it was a bit smaller than the head hole and the washer on top wasn't making a good seal. Like on the rear crank bearing seal, I made a mini rope seal soaked in gasket seal which was pushed down around the stud. A plastic crush washer was next, then a metal washer and nut. That seemed to fix it. It's a bit of a bodge, but I felt this was the least destructive way of sorting the problem and something that is reversible. It's got to be better than not being bolted down at all. |

|

|

|

| Before the first start, I turned the engine over on the starter to pump some oil and coolant around the engine. Then I was started ( see the video below ). It was run to temperature, cooled and re-torqued, then run again and re-torqued. I had a bit of a dash up and down the drive to put it under a bit more load and it is now cooling down again for another re-torque. I'll do another proper test drive tomorrow once Lynne is here so I have recovery assistance. |

|

|

|

| While tinkering, I also fitted a new clutch pedal and brake pedal spring. The old ones didn't have much spring left in them, giving a very limp clutch pedal. |

|

|

|