Ongoing Work in 2009

-----

| Aug 16th '09 - Ignition Fuel System Check

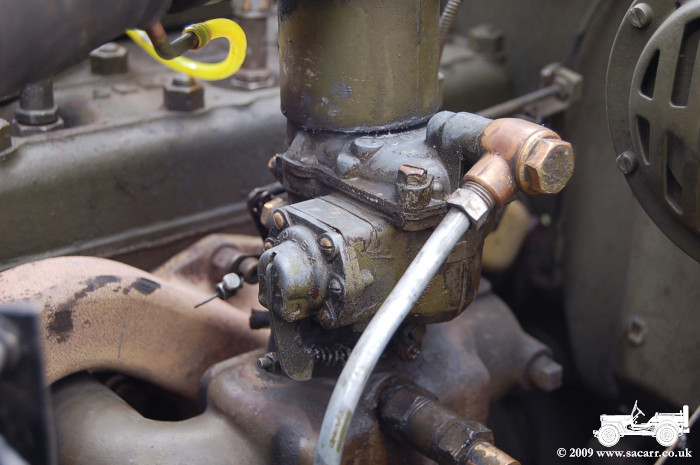

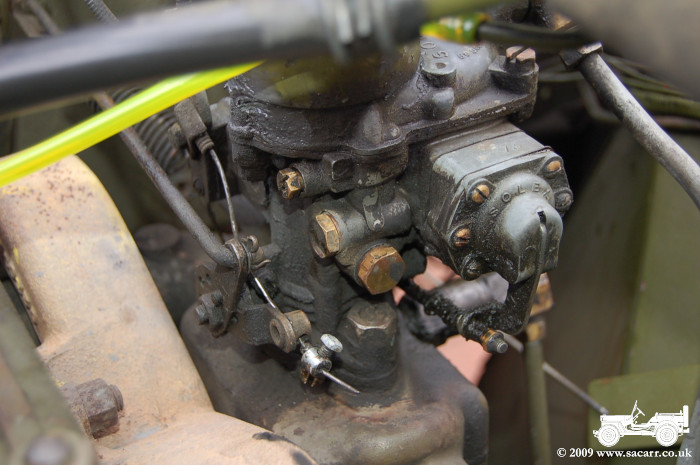

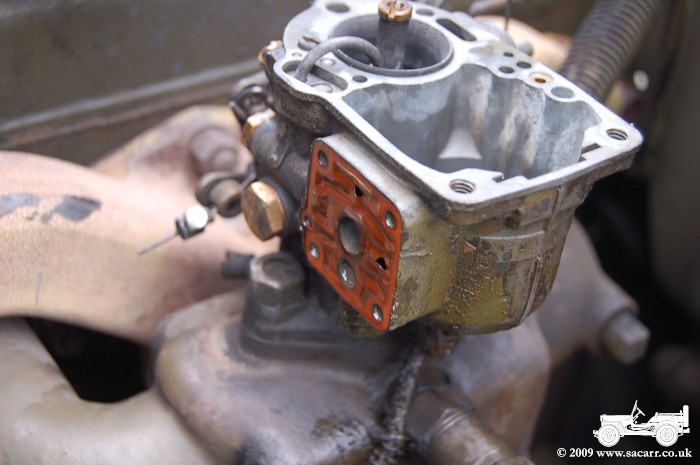

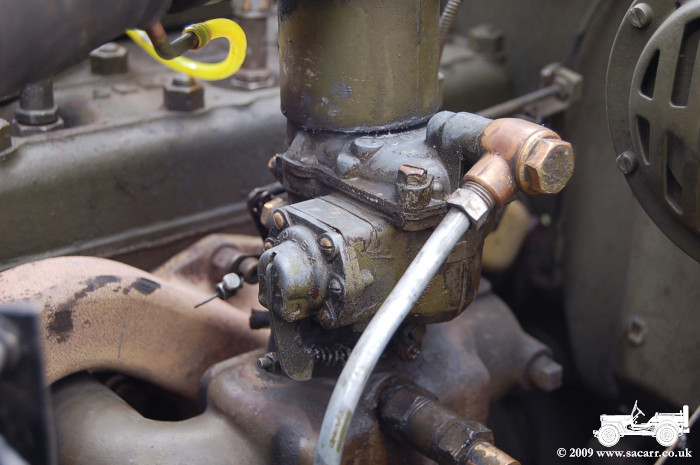

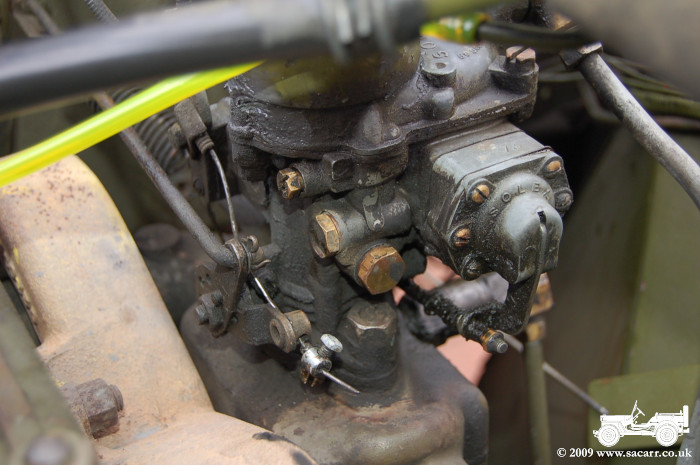

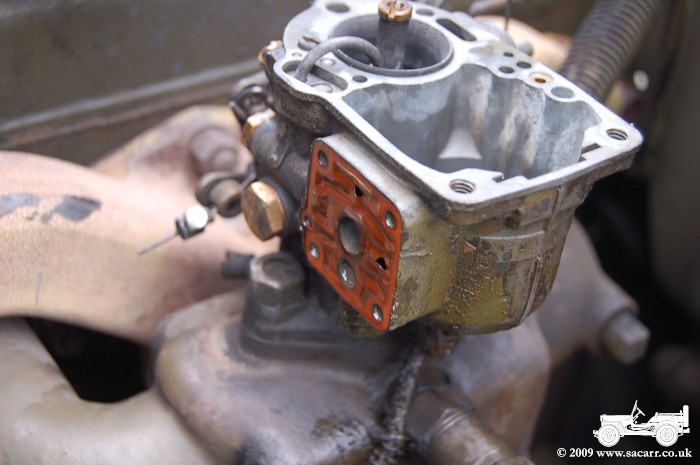

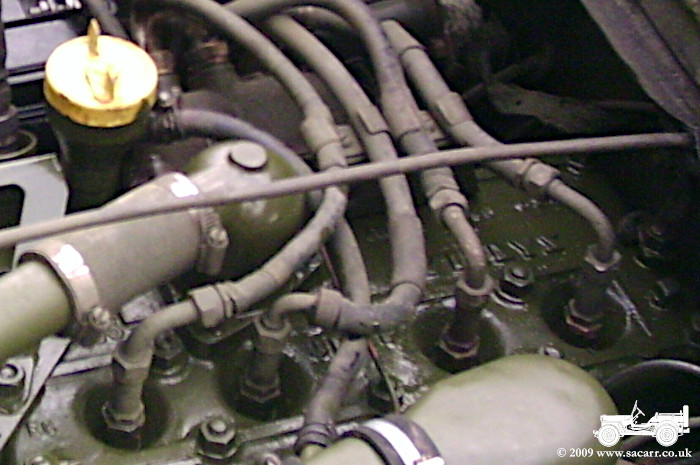

Over

the last few weeks, the Jeep engine has been miss-firing every so often,

particularly under acceleration loads. In an attempt to narrow down what

the problem was, I stripped down the carburettor to clean it and the

distributor to swap parts with a spare I had. The carburettor is

seen below in the first picture from the front left, showing the main

fuel feed pipe leading into the float chamber. The second picture is

from the front right, showing the throttle linkage to the left and

acceleration pump on the front.

|

|

|

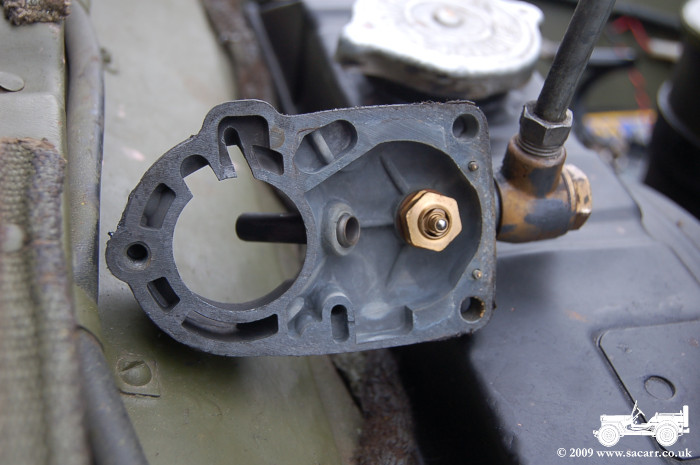

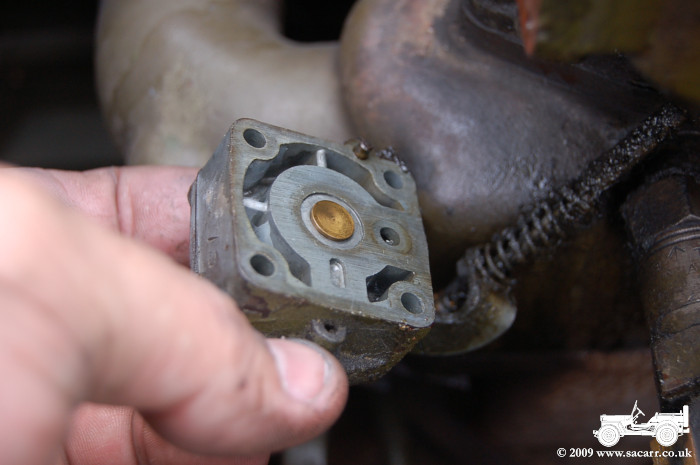

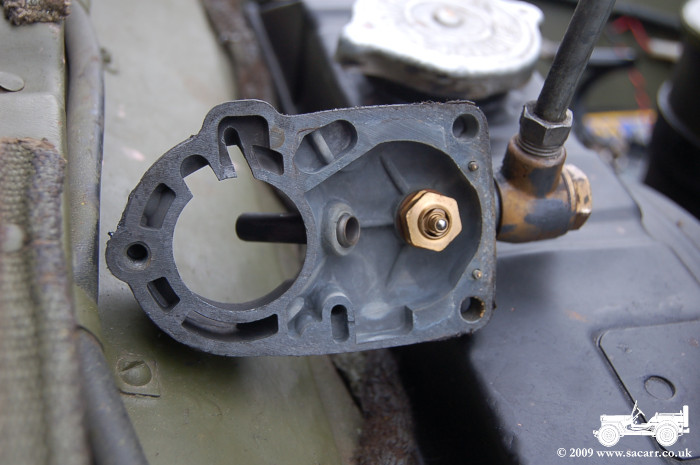

The

fuel pipe was disconnected from the fuel pump, and then the top of the

carb removed to reveal the float chamber ( below left ). The float was

removed and the bowl cleaned out of sediment. The cover plate had the

one way ball valve checked.

|

|

|

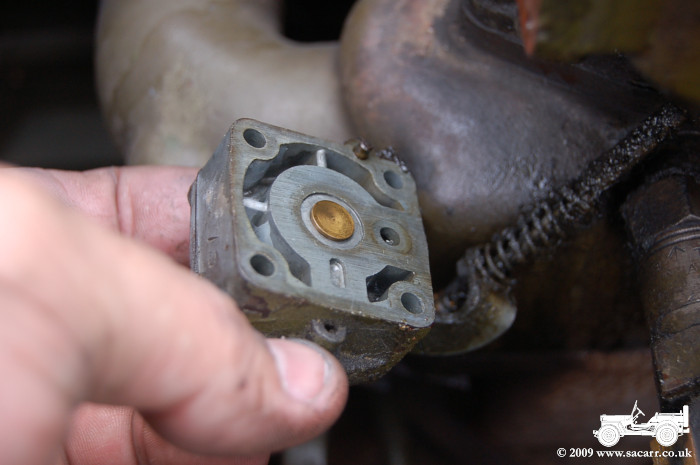

Next

the accelerator pump was removed and the pump checked that it was still

pumping fuel through the port. Several other jet screws were removed and

the areas flushed out.

|

|

|

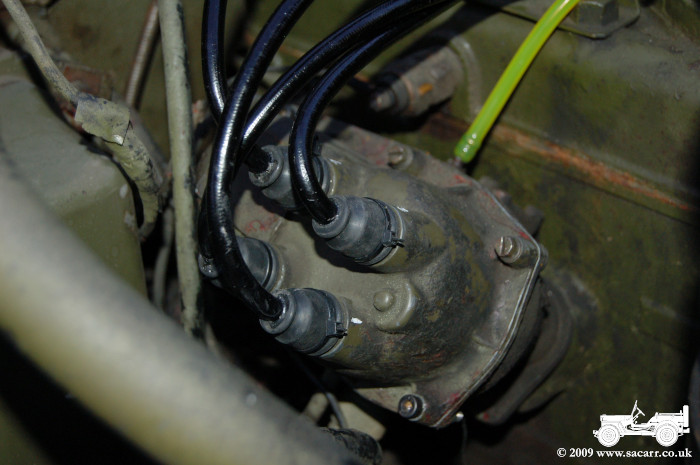

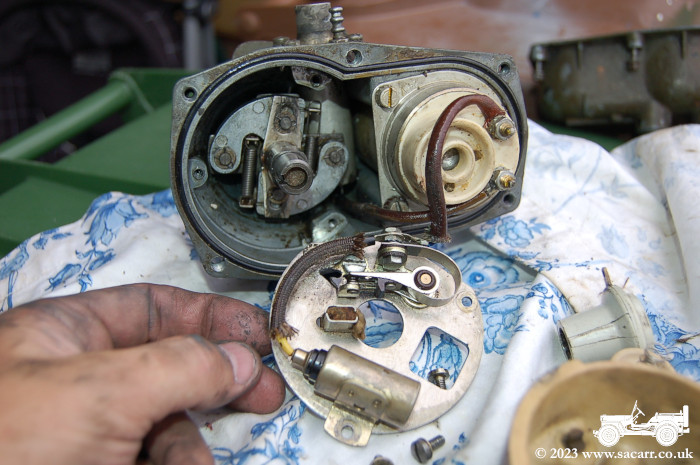

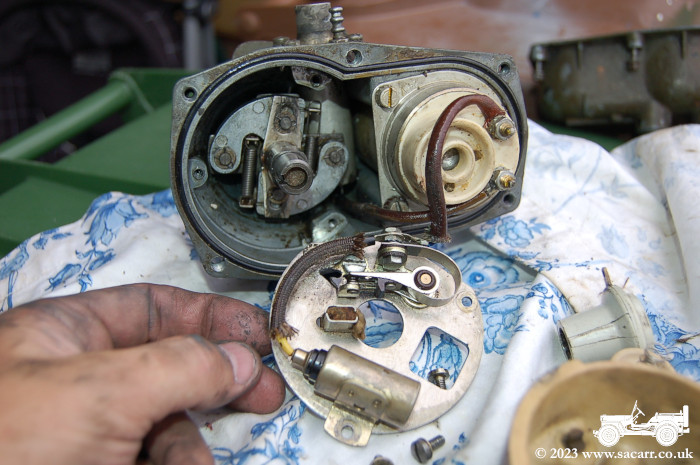

| The

distributor had the points cleaned and re-gapped, and the condenser

swapped for another old one off a spare distributor. The plugs were

removed, cleaned, re-gapped. At each stage the engine was test run to

check for improvements. |

|

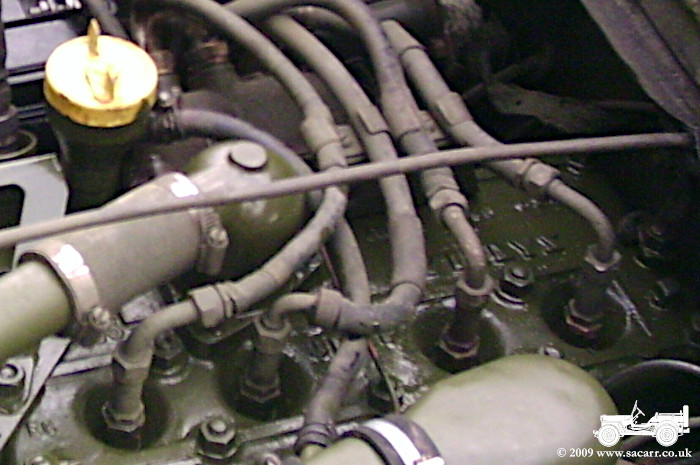

| The plugs in

cylinders 1 & 2 were running colder than 3 & 4, so they were

swapped with 3 & 4 and the engine re-run. This showed the plugs to

be ok as the plugs in cylinders 1 & 2 were still colder. No 1 &

2 HT leads were then swapped resulting in smoother running 99% of the

time. It seemed the HT leads were likely to be suspect, either

fractured or shorting.

First

thing Monday, I ordered some new points, condenser, HT leads and plugs

from Tony Sudds. Unfortunately Hotchkiss leads aren't that common so I

ordered Willys leads that would need altering to get them to fit the

screw to distributor.

|

|

-----

|

July 7th '09 - Door Modifications

At

last weekends event at Ingleton, we spent some of the time with the

front section of the doors unscrewed when it was warm, but it was a pain

screwing them back on when it rained.

I decided to make

them quick release so if I was driving with them removed, they could be

quickly re-fitted. To achieve this, I filed off the end of the

hinge pin, and replaced it with an 'L' shaped pin that would allow it to

be easily drawn out of the hinge.

The parts of the hinge can now remain screwed

to the doors, while the pin can be easily withdrawn and replaced along

with the doors. |

|

| To further enhance

the Flying Control look to the Jeep, the rear sections

of the door sets were also painted checkered today. This more resembles the

100th Bomb Group Follow Me Jeep in my 100th archives photo album. |

|

|

|

June 28th '09 - Distributor

Continuing from the plug clean, the

24v distributor as stripped and all the contacts cleaned. When it all went back

together, the engine wouldn't start! Two hours later after checking everything,

it still wouldn't start, but I had narrowed things down. There was a spark at

the points, and I was getting power through on the HT side contact on the

distributor. From there however, it wasn't delivering the power to the rotor arm

and on through the HT leads. After further cleaning and checking, I used a model

railroading product called 'Electro-lube', an electrically conductive oil. This

was added to the contact between the electrics and the distributor cap, and

between the contact in the cap and the rotor arm. It was all put back together

yet again and finally the engine started much to my relief!

-----

June 27th '09 - Plugs & Air Filter

The Jeep engine has been missing

occasionally and seemed down on power recently, so today the plugs were stripped

and cleaned. Unlike the standard Willys plugs, these are the sealed type with

the screw on ignition leads. Each plug can be split in two, and buy unscrewing

the top section, the centre terminal can be withdrawn allowing cleaning of it

and the contacts within the plug body. All the plugs were re-gapped and checked

for spark before fitting. The air filter was also removed, stripped, cleaned, a

load of creamy sludge removed from the bottom, re-oiled and re-fitted. A quick

road test showed the engine to be running much better.

-----

|

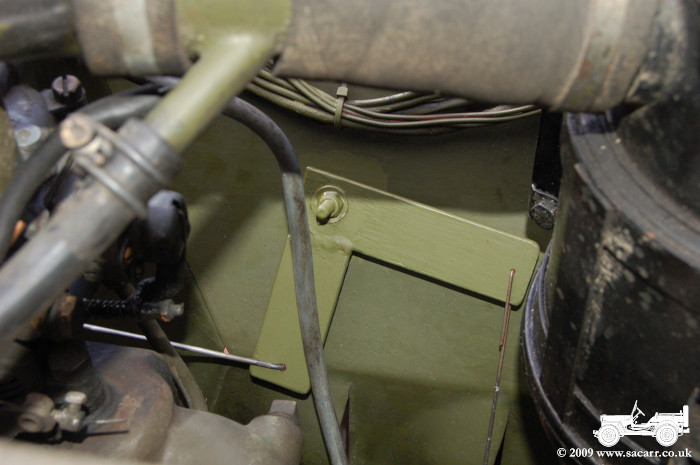

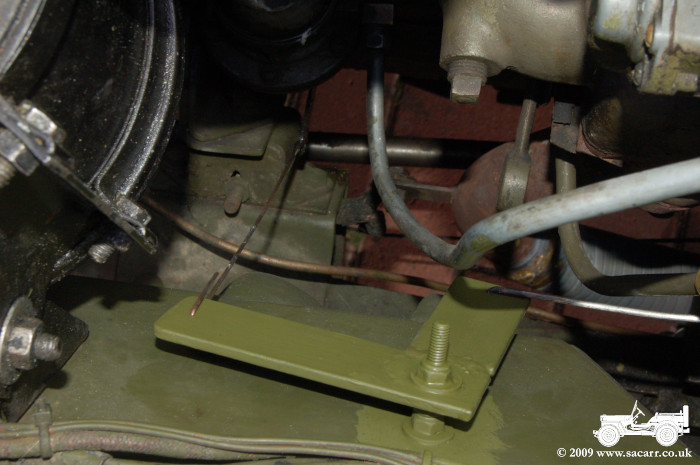

April 4th '09 - Engine Primer Modification

If

the Jeep hasn't been run for a while, the engine needs a prime before starting,

otherwise the batteries and starter get un-necessary use pulling the fuel

through. Previously I had fitted a

welding rod through the hole in the primer arm, and the

other end hung over the horn bracket. With the hood open I could pull this wire.

Reaching this wire is impossible when the

doors are fitted.

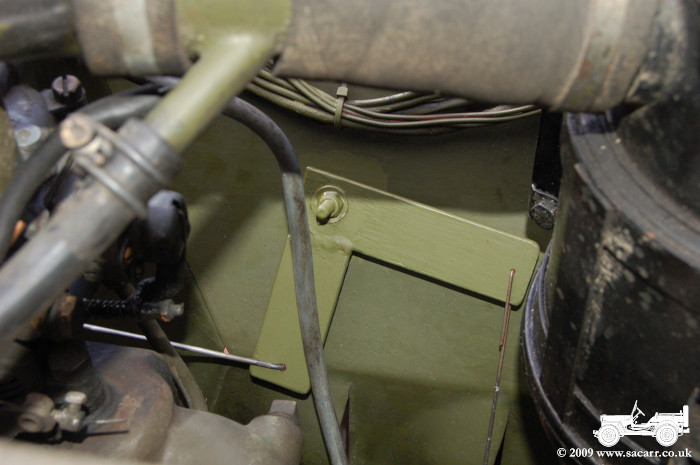

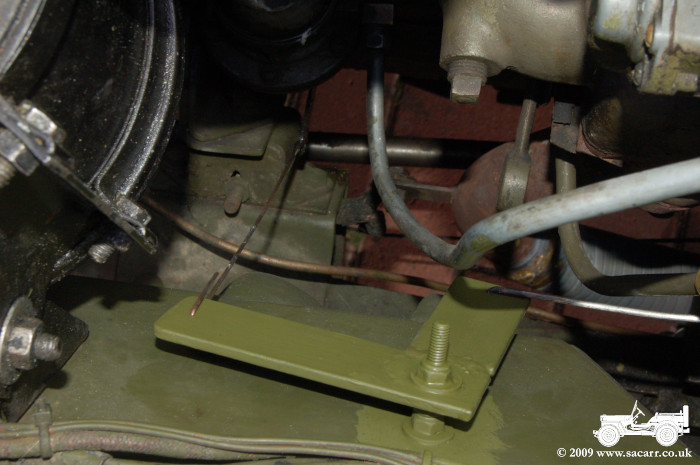

Today I

made this little bellcrank modification. The steel bellcrank was welded

up from scraps I had kicking around, and bolted through an existing hole

in the fender. The original priming wire was cut short and fastened to

one end of the bellcrank.

|

|

A piece of 2.5mm piano wire went into the

other bellcrank arm, and through an existing hole in the firewall,

exiting near the pedals and steering column. Now I can park with the

doors on and the hood shut, and to prime, just reach down by my feet and

push the little wire a few times. Job done!

|

|

|

-----

March 29th '09 - Trailer Wheel Bearings & Rust Treatment

With another good day

forecast, I had the trailer wheels to bits, mainly to grease the wheel bearings.

I also cleaned the loose paint and rust off the hubs and wheels, re-painted

them, greased the spring shackles, towing eye and oiled the springs. The Winter

Doors also had their plastic windows polished, as over the last couple of years,

they had become covered in tiny scratches, reducing the visibility through them.

-----

March 28th '09 - Rust Treatment

This weekend saw the inside

of the Jeep being treated for areas of rust along various seams. It was a cold

day which did slow up the painting, but because the doors were still on, I had a

2Kw fan heater in there with me which certainly made it a more pleasant job, and

did speed up the drying times! I'm sure it won't take long for the new

paint to weather in to match the old.

-----

March 21st '09 - Rust Treatment

For some time I've noticed a

row of rust blisters on the paint behind the axe and shovel. It was a nice day

today and while I was tinkering with other odds and ends on the Jeep I decided

it was time to deal with them. As with previous rust treatments, the affected

area was ground out with a wire brush, red oxide primed, filled level, re-primed

and the final colour coat painted. The axe and shovel were also cleaned and

woodwork waxed ready for re-fitting once the paint has hardened.

There was also a small area

just above the exhaust which needed the same treatment.

-----

| Winter Door Re-fit

The other

main job for the day was to modify the winter side doors to fit the

checkered canvas. With this canvas being slightly tighter, the front

edges of the doors needed trimming where they butt up against the

screen. Getting out of the Jeep in the garage is now a tight fit!

Smaller jobs done were to repair the

glazing on one of the trailer indicators and to start making a 'Follow

Me' sign to fit above the light box.

|

|

|

|

-----

March 17th '09 - Major Maintenance

The Jeep is now back from its

second round of maintenance at Croft Engineering. This time the major job was

the clutch replacement, but while it was in and stripped down, several minor

things came to light. Two oil seals were replaced, one on the transfer case and

the other on the front diff. The handbrake shoes were also replaced as one was

broken and they were covered in oil from the leaking oil seal.

-----

March 7th '09 - Fitting Reflectors

What I expected to be a quick

job actually took five hours. The bolts holding the old reflectors on were

rusted solid and had to be ground off with the angle grinder. The bodywork

behind had lots of surface rust and was very uneven where it had been pulled in

at the welds, so after the rust was removed and the surface red oxide primed, it

was filled and sanded to a more even level so as not to distort the reflectors

when they were bolted up. It was primed once again before a final brushed coat

of green. In the summer when it is warmer, I'll give the area a light sand and a

sprayed coat of green. Once the paint was dry, the new reflectors were bolted

on.

-----

-----

February 24th to 26th '09 - Major

Maintenance

Jessie went for some major

work that I was unable to do myself, which includes replacing the steering

bellcrank kingpin. I've tried on a couple of occasions to remove it and failed.

Croft Engineering, who did the work, finally managed to remove it with A LOT of

heat and a puller. The other work included replacing the steering gearbox

bearings, fitting the new brake shoes bought at Stoneleigh in 2008, re-setting

the valves, and a tune up.

During the Jeep's overhaul, I

was advised that the clutch needs replacing, something I've suspected for a

while. While it isn't slipping yet, we have several long trips planned this year

with the trailer, so it's likely to go back to Croft Engineering to have this

work done before the season really gets going. I've had the Jeep almost four

years and covered 7500 miles and this is the first major work it has needed so

it isn't doing too bad for a 51 year old vehicle, with some parts such as the

engine, 65 years old. The engine itself was given a leak down test and is

looking good with cylinder pressures all fairly close, ranging from 115 to 121

psi.

-----

|

February 1st '09 - Stoneleigh

Military Fair Purchases

Something that's been a bit

tatty for a while is the reflectors, Hotchkiss ones, one of which was cracked.

Because the Jeep I originally copied was an early type, I got some NOS 'Tiger Ey'

reflectors.

|

|

| Also purchased was a Jerry Can strap and two footman loops. The

loops will be fixed to the back of the drivers seat and floor to hold the Jerry

Can on longer distance trips where we don't have the trailer.

|

The last purchase for the

Jeep was a bearing set for the steering gearbox which has been showing signs of

play in the output shaft.

|

Home