The inside of the rim was reinforced with carbon fibre 'tows'. These were again attached with polyester resin.

The outside of the helmet was still rough from the glass matting, so it was sanded to remove the high spots and filler added to the low areas.

Once fairly smooth, a coat of filler primer was sprayed on. The rim edge was built up with filler against the edge of masking tape.

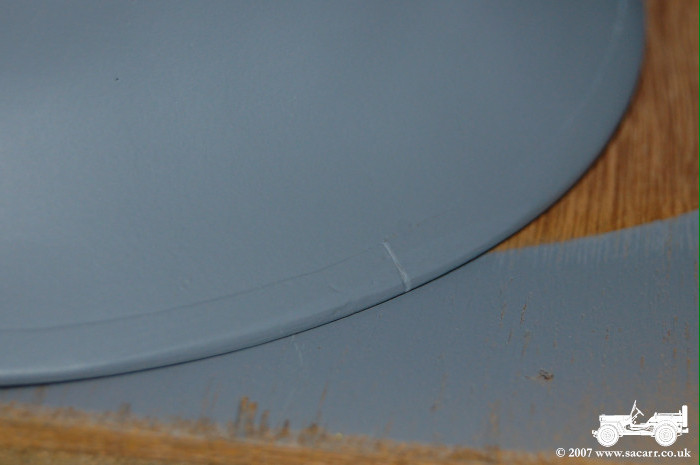

The tape was removed leaving a slight lip as per original and a slight grove added to represent the seam.

Another coat of primer was sprayed on showing up any pinholes which were filled before being rubbed down and sprayed again.

Finally a coat of olive drab. A set of reproduction straps have been ordered to fit. Now it just needs the red crosses adding.

Ground cork was sprinkled into the wet paint followed by another coat to give the 'corking' effect. Red crosses were then added.

Straps are now added, though one needs re-attaching shorter as there isn't enough adjustment.