| July

1st - Engine Bottom End Rebuild.

Since the trip to Suffolk, the engine has been weeping oil from the clutch bell housing. It must have been escaping past the rear crankshaft seal, and then running into the housing. Over the last few short trips, the weeping has turned into pouring, leaving a three to four inch diameter pool of oil within a short time of parking. I tried a different grade of oil, but that made no difference. Weeping I could have lived with, but not with the current loss rate. The engine had to come out and be inspected. On Wednesday July 1st, I began with a short run to

warm the oil which was then drained. The battery was removed next,

followed by draining the radiator. With that done, I started

disconnecting things, starting with the headlight wiring which allowed

removal of the grill. Radiator hoses off, radiator out, throttle

link and carb off, fuel supply pipe off, cylinder head temp sensor out,

earth strap off. The list went on until I was at a position to lift the

engine, then called it a day. |

|

|

|

| July

2nd

On

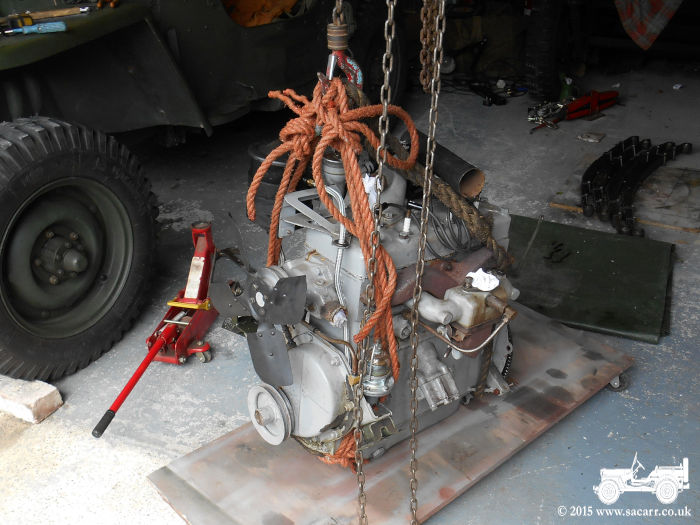

Thursday 2nd, the exhaust was disconnected, then the starter and

alternator were removed. This gave better access to the bell housing

bolts. Next was the engine mount bolts and bell housing bolts, followed

by slinging ropes around the engine for the lift. |

|

|

|

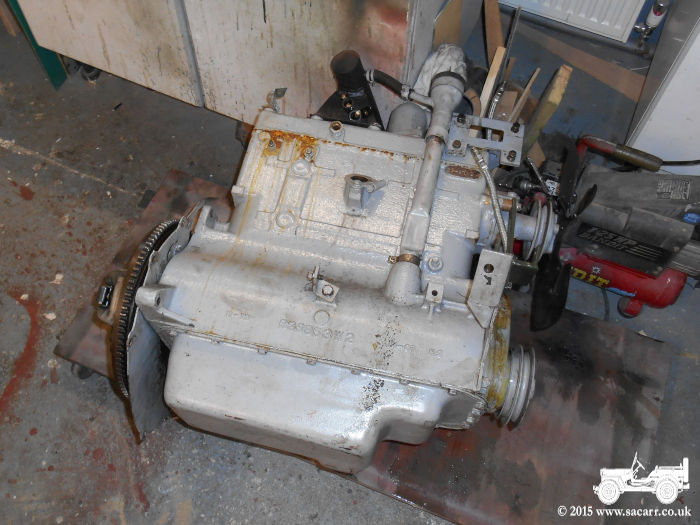

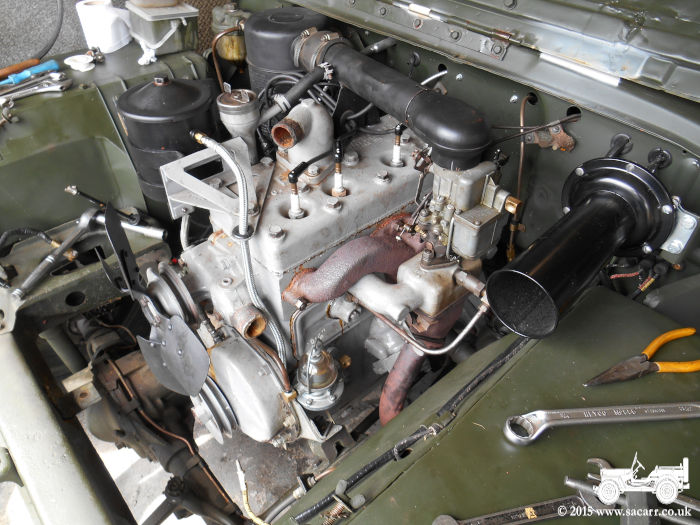

| The

engine was lifted out with a bit of wiggling, and lowered onto a trolley

which could be used to move it to the workshop. Before the move, the

inlet manifold, oil filter, fuel pump and coil were removed, as the

access was better than in the Jeep. One last step was to tip the engine

on its side, resting on some blocks of wood, so I could access the sump

bolts. It was a baking hot day, and that was enough hard work in the

heat, so it was wheeled into the workshop, and I cleaned up. |

|

|

|

|

|

| July

3rd

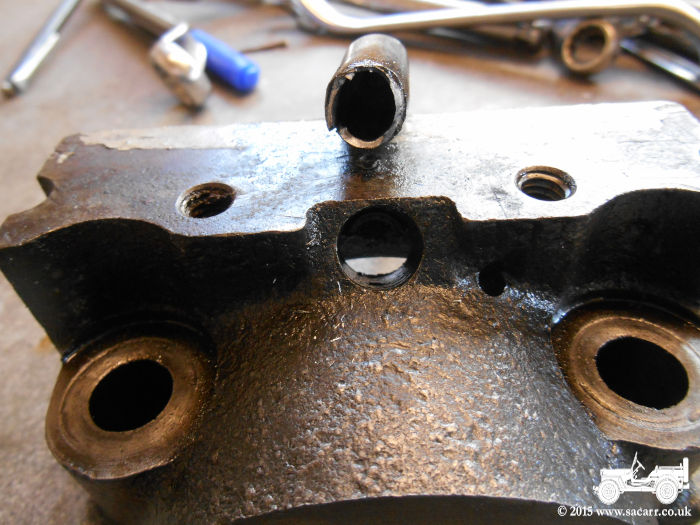

I found the source of my oil leak today. First thing off was the oil sump. Love the way the Jeep manual says.... "remove the six nuts and washers from the flywheel, and then tap flywheel free with a brass hammer."

It mentions nothing about the Oxy/Acetylene torch and beating the crap out of it for two hours. The engine end plate came off after that, allowing better access to the rear crank seal. |

|

|

|

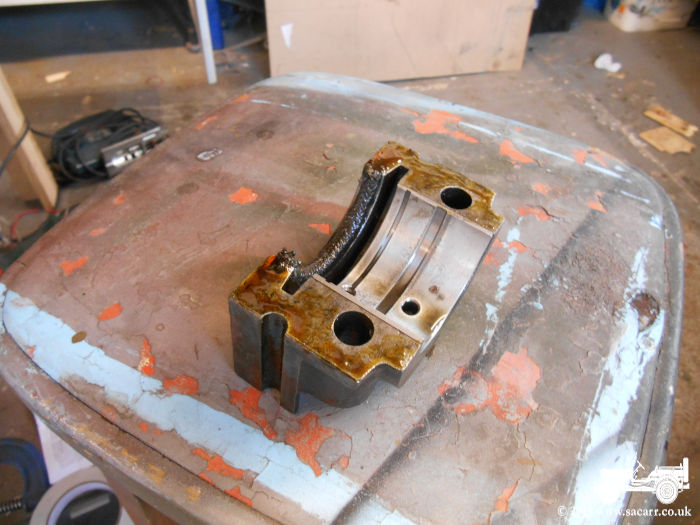

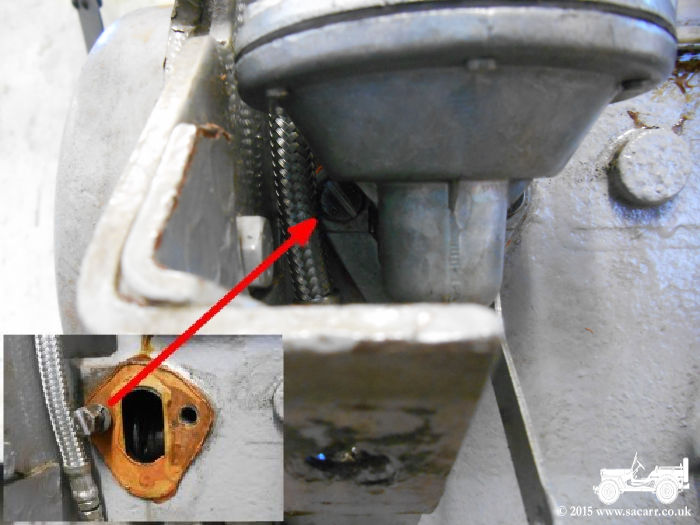

| It seems that when the engine was rebuilt, the rubber seal had been stuck in with silicone. This had come loose, working its way around to the oil drain hole and blocking it. The rubber seal shows signs of friction burns and had also split. Apparently the rubber seals aren't great anyway, and most parts suppliers suggest the rope seal. So replacements were ordered. | |

|

|

|

While chatting to one supplier, he also suggested removing the oil drain pipe down to the sump. This allows a larger hole for the oil to drain through, reducing pressure on the oil seal. Removing it opened up the drain hole from 9.5 to 12.5mm bore. Later engines don't have this pipe. Total time so far is only three, half days on the job, so there's a good chance I could have the Jeep back on the road by next weekend. |

|

|

|

| July

4th

The postman brought the bits and bobs today, so I was able to make a start on putting it all back together. The bottom seal was an easy fit, but getting the top one in past the crankshaft was a nightmare. It too could have been an easy job by removing the crankshaft. However, that would have involved removing the pully off the front, the timing chain off, the pistons all disconnected and crankshaft out. In the end, that would have made it a much bigger job. Once the seals were back in, the sump float

was refitted, followed by the sump. |

|

|

|

|

The engine backplate was fitted next, followed by

the flywheel and then clutch. The clutch disc was aligned with an old

gearbox shaft. I then turned the engine upright, and lashed it down to

make sure it wouldn't tip over. While the engine was out and easily

accessible, I reset all the valve clearances. |

|

|

|

|

Again, while the engine was out and bits removed,

I modified one of the fuel pump bolts. It is in a really bad position for

access, wedged between the fuel pump and oil line. I don't have a socket

that will fit the space, and you'd a really odd shaped spanner to avoid

the oil pipe and pump. So my fix was to fasten two hacksaw blades together

and cut a slot in the top of the bolt, allowing a broad blade screwdriver

to be used to tighten it.

Last job of the day was to refit the

inlet/exhaust manifold. |

|

|

|

|

July 5th

Last day working on the Jeep ( I hope ). Wheeled the Jeep forwards so I could trolley the engine from the workshop to the garage; then pushed the Jeep back to give clearance to hoist the engine around the front of the left fender and blackout light. After a bit of jiggling, I got the engine back in and began the nightmare of bolting up the clutch bell housing. I don't recall having problems getting it apart, but could have really done with some odd shaped spanners, very bendy arms and magnetic fingers to get the bolts and nuts back in place, especially the top ones right against the firewall!

I'd already modified the coil bracketwhich means I don't need to fully

remove the nuts to take it on and off. They only need to be slackened a

little. |

|

|

|

|

Other engine accessories were fitted next such as the coil, carb, and starter.

Throttle linkage and exhaust were next. Radiator and hoses after that, and the radiator filled. |

|

|

|

|

The engine oil had only done 12 miles and was drained into a clean container when I started the job. Today it was strained through a cloth to refill the sump.

I left the grill off to start with in case I was going to have to pull the

engine out again.

I did a few runs in the garage, checking for oil and water leaks. The oil filter housing lid was leaking a bit, so put some sealer around the rubber seal and that sorted it. Once it was up to a reasonable running temperature, it was idling with 12 to 15 PSI oil pressure and 20 to 30 PSI with a few revs, which is all ok. I then refitted the grill. |

|

|

|

| So far, no oil weaping from the rear seal and running out of the bell housing. It was getting a bit late for a test drive today, but so far, all appears well. | |

|

|