| November 7th - Time

to fix the Tank Sender Since getting the Jeep on the road, the fuel tank gauge hasn't worked. This was traced to the sender, and more exactly, a cork float that wasn't floating. The float was absorbing fuel and sinking. Back in July, I made a sample cork float, coated in epoxy to seal it. This was placed in a jar of petrol and left. A week later, it was still floating. No more progress was made until today, when the jar was inspected and the cork sample was found still floating. The next step was to remove the sender from the tank. It was given a quick dry and the varnish that had been on was sanded off. The float was then left in front of a hair dryer to completely dry out. |

|

|

|

Once the petrol had evaporated out, it was placed in a sink of water, to check that it would actually float; and it did! Before it got too wet, it was removed and dried again. Once it had another good bake in front of the hair dryer and then I started mixing epoxy to coat the cork. Once it was touch dry, it was left in the airing cupboard to harden off and fully cure. After a while curing, it was refitted and connected up. With the ignition on, the fuel gauge lifted up to the empty mark, but there isn't a huge amount of fuel in right now. After bouncing the Jeep side to side on its springs, I could see the gauge needle lifting and falling slightly, so I think I've got it sorted. I'm hoping to attend the aircraft museum Remembrance service on Sunday, so I'll add some more fuel then which will hopefully show the problem is fixed. |

|

|

|

| -----

Oct 31st - A Good Wash Since Croft in August, the Ford has needed a good wash to get the mud off, but I didn't fancy pushing a wet Jeep back into the garage. With the new starter motor fitted, and the Jeep back up and running again, it is now easy to get it in and out of the garage. For the cost of six sweeties, little legs did most of the donkey work, getting soaking wet in the process, but having a wonderful time! Anyway, she needs to look after her inheritance! |

|

|

|

|

|

| ----- | |

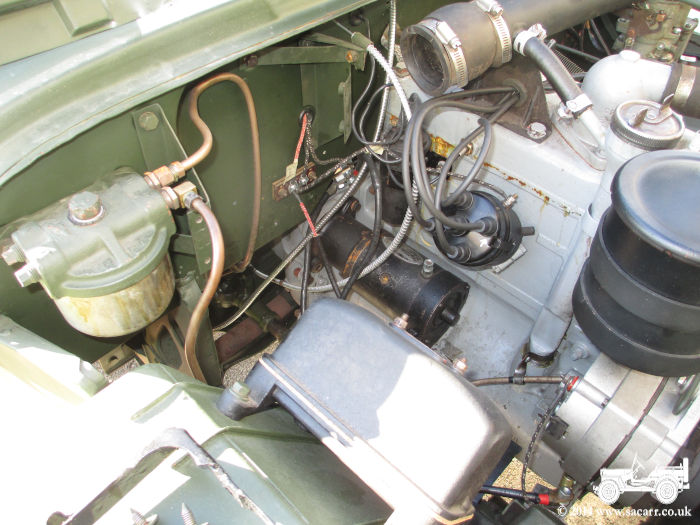

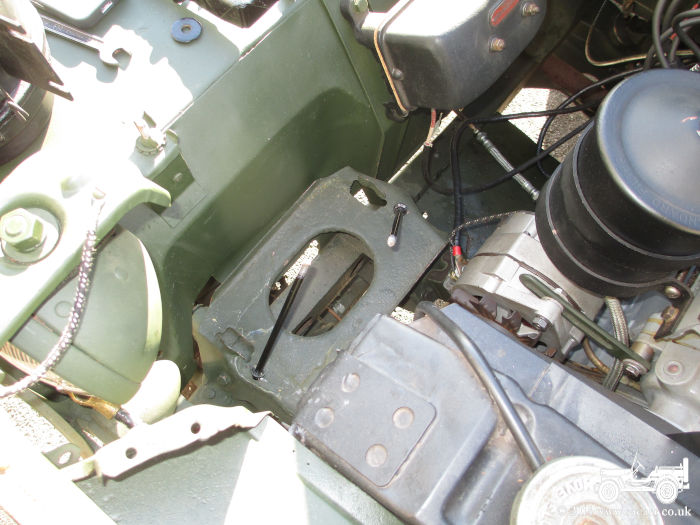

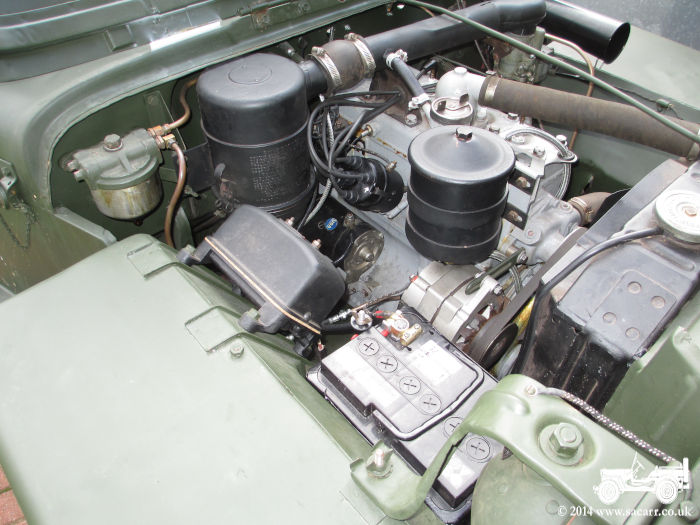

| Oct 11~13th -

Starter Motor Replacement

At Croft Nostalgia in August, I began to have starting problems with 'Hope'. I suspected the starter, but couldn't rule out the new battery. It took until October before I had a chance to take the battery out and back to Halfords for testing. Their load meter said it was fine, so concluded the old 6 volt starter was to blame, especially as I was starting to get burning smells from it. So while I was ordering valves and gaskets for "Jessie's" engine rebuild, I also ordered a new 12 volt starter for Hope. To replace the starter, the air filter had to come out, and the battery was already out from being tested. This left plenty of room to get in at the starter mounting bolts. The first three pictures show the old starter on the way out. The last two are of the reassembled engine bay with the new starter buried down at the bottom. After a good prime, the engine turned over easily and started without trouble. Now only a dodgy horn connection and the fuel tank float to fix. |

|

|

|

|

|

|

|

| ----- | |

| July 22nd - Fuel

Tank Float

After discovering the float problem the other day, or lack of floating, I decided to do an experiment. I had some old cork floor tile spare, so cut some up and glued it together into a small cube. This was then painted in epoxy resin to seal the cork and hopefully keep it petrol proof. The cube was then dropped into a jar of petrol and left to bob about for several days. If

this works, I plan to remove the sender again, completely dry out the

cork float and then epoxy seal it. It can then be refitted and hopefully

the float will then float, giving correct fuel level readings. |

|

| -----

July 20th - Springs and Fuel Tank Sender The

two replacement front springs were fitted on Thursday, and now it was

time for the rear two. They went on more easily than the front ones, but

there were still bits that put up a fight to come off or go back on!

Next one of the studs on the spare wheel carrier sheared, so that had to

be welded back on. |

|

| -----

July 17th - Springs The original Ford springs are very tired, and not supporting the Jeep any where near its correct height. This wasn't apparent during the rebuild until the body and front end were added. By that point, I wanted the Jeep complete in order to get the paperwork and registration process under way. Now that it is up and running, I am able to tinker with it's little niggles at my leisure. I have found a local company who will hopefully be able to reform and re-temper the original springs, but to do that, I needed them off the Jeep! With two Jeeps parked in the garage, I don't have the space to remove them there, leaving the Jeep on axle stands; so all the work must be done on the driveway. This means I needed to be able to put the Jeep away afterwards. Fortunately a friend had replaced the springs on his Hotchkiss Jeep, and still had the old springs. I have borrowed these to fit to the Ford, allowing it to stay mobile while the original springs are refurbished. I picked them up on July 17th, and by the end of the day, had the two front springs swapped, 'though with a pause between each while I packed up and collected my daughter from nursery. The picture below shows the Ford spring top, and the Hotchkiss spring bottom. The tired Ford spring is noticeably longer than the Hotchkiss spring, allowing the Jeep to sit much closer to the ground than it should. |

|

|

|

| The front left spring fitted showing the increase in height. | By mid evening, the second front spring was in place. |

|

|

| -----

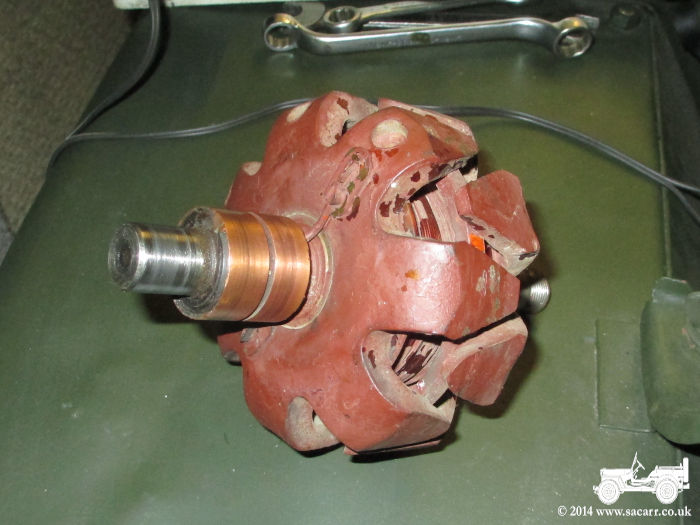

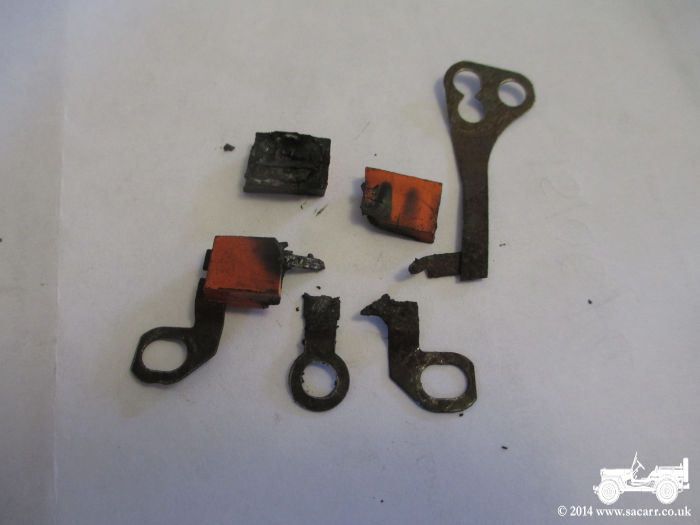

July 12th - Alternator Since getting the GPW on the road, the alternator hasn't worked, despite allegedly being tested by an auto-electrician. So, having failed to detect any voltage or current from it with my multi-meter, I pulled it to bits to looks for anything obvious. The only thing that wasn't looking too healthy was the rectifier diode, which was very black and charred, and dissolved into several pieces as it was removed. I've ordered a spare, which will hopefully fix the problem of charging. |

|

|

|

|

|

|

| -----

June 6th - D-Day Drive |

|

| On the

70th Anniversary of D-Day, I had to take the Jeep out for a drive.

I had a few errands to do anyway, and the longer run out would be good for the Jeep, and my confidence in the vehicle. A trip to the model shop in Chester-le-Street was first, around a 14 mile round trip. This was the longest and fastest trip yet, reaching 40mph. This was followed by a 2 mile trip to B&Q and back. After that, I reset all brake shoes and free play on master cylinder. Later in the evening, I dook my dad out for a short ride of a few more miles. By the end of the day, the Jeep had 31.6 miles on the clock. |

|

| -----

May 1st I was looking on Ebay for a Jack for the Jeep, and spotted a nice screw jack. It looked familiar, then I suddenly realised I already had one amongst some old tools I'd been cleaning up last year. The jack was the perfect size, and in the box with the jack, were a number of other tools that would be useful in the Jeep, including a plug spanner and wheel nut wrench. |

|

|

|

| April 21st

On the 21st, I took the Ford out on its fourth test drive. The first three trips were short on the first day the insurance started, and weren't far from the house, only a couple of streets away. This drive was the longest run so far, a 3 mile round trip to visit George, who had helped me with the trial fitting of the tub. George had been to see the Jeep the first day I tried to start it, but was unsuccessful, so this was the first time he had seen it complete and running. He looked quite at home in the hot seat, and I did wonder if I was going to get him out again. I got there and back without any problems as I slowly gain confidence in the mechanics of the vehicle. |

|